Three Five Acis Servo Series in Delhi

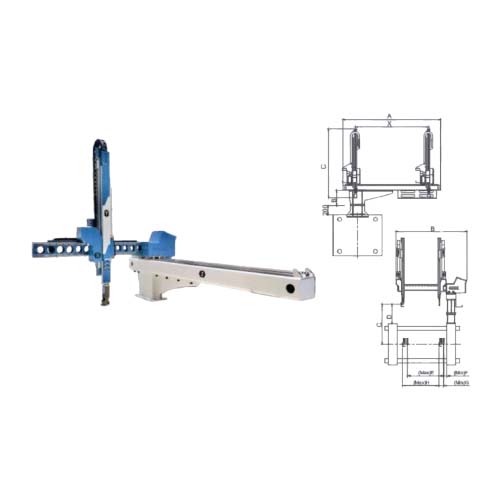

Three Five Acis Servo Series

Applications:

- General application for IMM article take out or insert molding

- Durable structure design for One axis or Three axis servo robot.

Three Five Acis Servo Series in Delhi

Applications:

- General application for IMM article take out or insert molding

- Durable structure design for One axis or Three axis servo robot.

Advantages:

- High Speed

- Durable Structure

- More flexible for Downstream automation

| Models | A | B | C | D | E | F | G | H | I | J | X | Y | Z | A.P.L (KG) | I.M.M. (Ton) |

| DH-2308 | 1600 | 300 | 800 | 60 | 620 | 80 | 680 | - | - | - | 620 | 800 | 1500 | 5 | 100-180 |

| DH-2508 | 1600 | 300 | 800 | 60 | 620 | 80 | 680 | - | - | - | 620 | 800 | 1500 | 5+3 | 100-180 |

| DH-2310 | 1840 | 300 | 1000 | 60 | 620 | 80 | 680 | - | - | - | 620 | 1000 | 1500 | 5 | 200-350 |

| DH-2510 | 1840 | 300 | 1000 | 60 | 620 | 80 | 680 | - | - | - | 620 | 1000 | 1500 | 5+3 | 200-350 |

| DH-2312T | 1700 | 340 | 1200 | - | 800 | 160 | - | 1750 | 2240 | 340 | 850 | 1200 | 1800 | 10 | 400-550 |

| DH-2512T | 1700 | 340 | 1200 | - | 800 | 160 | - | 1750 | 2240 | 340 | 1100 | 1200 | 1800 | 7+5 | 400-550 |

| DH-2314T | 1950 | 340 | 1400 | - | 1000 | 160 | - | 2000 | 2280 | 340 | 1000 | 1400 | 1800 | 10 | 600-800 |

| DH-2514T | 1950 | 340 | 1400 | - | 1000 | 160 | - | 2000 | 2280 | 340 | 1000 | 1400 | 1800 | 10+5 | 600-800 |

For industries in Delhi, the Three/Five Axis Servo Series offers unmatched precision, flexibility, and speed in robotic part handling, stacking, insert loading, and in-mould labelling.

Whether you're running a plastic injection moulding unit or a precision metal processing line, servo robots provide seamless multi-directional movement with pinpoint accuracy — ensuring improved productivity and product quality.

Key Features of Three/Five Axis Servo Series:

-

Full Servo Motor Control

All axes (X, Y, Z, and optional A/B) powered by high-performance servo motors for smooth, synchronized motion. -

Customizable for Complex Tasks

Ideal for multi-cavity moulding, insert placement, stacking, trimming, and packaging. -

Touchscreen Smart Control System

Easy to program, store, and modify tasks for various moulding operations. -

Energy-Efficient & Low Maintenance

Built for long-term use with optimized power consumption and minimal wear parts.

Get In Touch

Please fill out the form on this section to contact us.

-

Address

Street No-4, Plot No-2, Mundka Industrial Area, Delhi - 110041 India

-

Contact Us

-

Support Email